Variations in pore structures and permeabilities of the ion-adsorption rare earth ores in the zones with different weathering degree before and after leaching

-

摘要:

离子型稀土矿是典型的风化壳淋积型稀土矿,这类稀土矿浸出前后渗透性变化是反映稀土矿浸出率的重要指标之一,孔隙结构是控制其渗透系数的关键因素。以往对浸出前后稀土矿孔隙结构和渗透性研究主要集中于风化程度和丰度相对较高的全风化带稀土矿,对其他风化带稀土矿的研究较少。随着稀土资源日渐枯竭,其他风化带稀土矿的开发已受到产业部门的高度重视。研究以江西足洞矿区未开采段残积土、全风化带和强风化带内的原状稀土矿试样为研究对象,通过模拟原地浸矿试验,测试其浸出前后渗透系数,采用X射线计算机层析扫描技术获取浸出前后试样结构,采用三维成像技术构建其三维孔隙结构、提取孔隙结构参数,进而定量分析不同风化程度稀土矿浸出前后孔隙结构参数和渗透系数变化规律。结果显示:(1)浸出后,稀土矿渗透系数和孔隙结构参数中的孔隙度、连通性及平均配位数变化率随风化程度降低呈现减小趋势。其中,强风化带稀土矿的渗透系数和孔隙结构参数变化率最小,反映在丰度相近时,强风化带稀土矿较残积土稀土矿的浸出率更高;(2)浸出前后颗粒级配和矿物成分变化特征显示,不同风化带稀土矿浸出前后孔隙结构和渗透性变化率差异的内在机理是长石及云母颗粒分解作用、离子交换作用强度和团粒分散程度的差异以及由此导致的矿物成分和颗粒级配变化程度的差异。研究结果可为类似离子型稀土矿的充分开发利用提供参考。

Abstract:Ion-adsorption rare earth (RE) ore is a typical kind of rare earth ore derived from the weathering crust of igneous rocks. Variation in permeability of ion-adsorption rare earth ore is one of the indicative factors of mining efficiency. Permeability of the RE ore is controlled by its pore structure. Previous studies mainly kept on the RE ores in completely weathered zones, little on those in the zones with other weathering degrees. With the exhaustion of rare earth resources in the completely weathered zone, the extraction of the RE ore from the zones with other weathering degrees has gained more attention from the industrial sectors. This study shows a study on variations in pore structures and permeabilities of the RE ores in the zones with different weathering degrees, including the residual soil and completely weathered and highly weathered zones. The undisturbed samples were taken from an un-mining section of the Zudong mining area in Jiangxi province. Simulated in situ leaching experiments were conducted on the samples to measure their permeability coefficients before and after leaching. X-ray computer tomography scanning techniques were applied to the capture structure of the samples before and after leaching, and image processing techniques were used to construct their three-dimensional pore structure and extract their pore structure parameters. Variations in pore structure parameters and permeability coefficients of the RE ores from the zones with different weathering degrees were then carried out by a quantitatively comparative analysis. The results indicate that (1) the variation rate in permeability coefficient, and the pore structure parameters, including porosity, connectivity, and average coordination number, decrease with the decrease in weathering degree. Notably, these variation rates for the RE ores in the highly weathered zone are the smallest, indicating the RE ores in this zone are more leachable than those in residual soil if their abundance is not much different. (2) The mechanism leading to their differences was further investigated by the analyses of particle size distribution and mineralogical composition before and after leaching. The analysis results indicate that the differences in their variation of pore structure and permeability among the RE ore in the zones with different weathering degrees are caused by the differences in followings during leaching, including the chemical decomposition of plagioclase and mica, ion exchange, and disaggregation.The results can provide reference for the full development and utilization of similar ion-adsorption rare earth ore.

-

离子型稀土矿是重稀土的矿源,又称风化壳淋积型稀土矿,主要存在于花岗岩、火山岩风化壳中。残积土、全风化带和强风化带是离子型稀土元素的主要富集带,中风化带和基岩则是原地浸矿渗流底板[1]。富集稀土的不同风化带中,全风化带丰度相对最高,强风化带和残积土中丰度相对较低,但丰度差异不大[2]。离子型稀土矿中稀土元素以水合阳离子或羟基水合阳离子的形式吸附在风化壳中黏土矿物表面。采用含活性阳离子(如Na+、NH4+、Mg2+和Al3+)的化学溶液进行离子交换是目前唯一实用的离子型稀土矿开采工艺[3 − 4]。原地浸矿开采是目前最主要的稀土矿开采工艺[5]。浸矿液在稀土矿中的渗透性决定浸出率,孔隙结构则是控制其渗透性的关键因素。

孔隙结构和渗透性一直是离子型稀土矿开采研究中的热点问题[6 − 9]。然而,多年来稀土矿开采以“采富弃贫、采易弃难”模式为主,因此已有研究都聚焦于风化程度高、丰度高的全风化带稀土矿,极少关注残积土和强风化带中稀土矿的浸出。对于全风化带稀土矿,前人研究已经形成的基本共识是,浸出后稀土矿的孔隙结构和渗透性急剧减小,导致稀土矿浸出率急剧降低[6 − 9]。近年来,由于离子型稀土资源日渐枯竭,加之国家实施更严格的保护性开采政策,开采丰度较低的其他风化带中的稀土矿已受到产业部门的高度重视。因此,研究不同风化带的稀土矿在浸出前后孔隙结构和渗透性变化规律,不仅可从理论上丰富对稀土矿孔隙结构与渗透性的认识,更可为稀土矿充分开发提供重要的理论依据。

江西、广东、广西等南方7省是我国离子型稀土矿的主要分布区,其中以江西赣州的离子型稀土矿资源最为丰富,稀土元素配分也最为齐全[10]。本文以江西省赣州市龙南足洞稀土矿为研究区,在矿区内未开采区一处典型断面的残积土、全风化带和强风化带中采集原状试样,通过室内模拟原地浸矿试验,测试浸出前后试样渗透系数;同时,采用X射线计算机层析扫描(X-ray computer tomography, X-CT)技术获取浸出前后试样结构,基于三维成像技术构建试样三维孔隙结构、提取孔隙结构参数,进而定量分析不同风化带稀土矿试样浸出前后孔隙结构变化特征及其与渗透系数关系;基于颗粒级配(particle size distribution, PSD)和X射线衍射(X-ray diffraction, XRD)技术,分析浸出前后颗粒级配、矿物成分的变化,探讨浸矿后不同风化程度稀土矿孔隙结构、渗透性变化及其程度差异的内在机理,以期为稀土矿的充分开发利用提供理论依据。

1. 试样采集与研究方法

1.1 试样及其基本特性

江西赣州龙南足洞稀土矿是最早被发现的离子型稀土矿区,属于典型的高钇重稀土矿,其成矿母岩为燕山期中粒黑云母花岗岩[11]。本次研究试样取自足洞稀土矿区未开采区域内的一处边坡断面上。在同一垂直剖面上,从残积土、全风化带和强风化带中采集 3 组原状试样,编号分别为1-1、2-1、3-1,见图1(a)(b),试样基本物理性质见表1。试样用特制取样器采集,取样器由内径25 mm、高120 mm钢管和放置于其中的外径25 mm、高120 mm聚碳酸酯管组成,见图1(c)。取样过程为:先将取样器快速压入风化带中,后将装有试样的聚碳酸酯管连同试样一起从钢管推出,用帽盖将聚碳酸酯管的两端盖住,见图1(d)。同时,在取样部位采用环刀采集原状样、挖掘10 kg扰动样,分别用于密度、颗粒级配、矿物成分及稀土含量测试。风化带粒度组成的测定采用筛分和激光粒度分析相结合的方法,大于0.075 mm的颗粒采用湿筛法,小于0.075 mm的颗粒采用激光粒度分析方法。

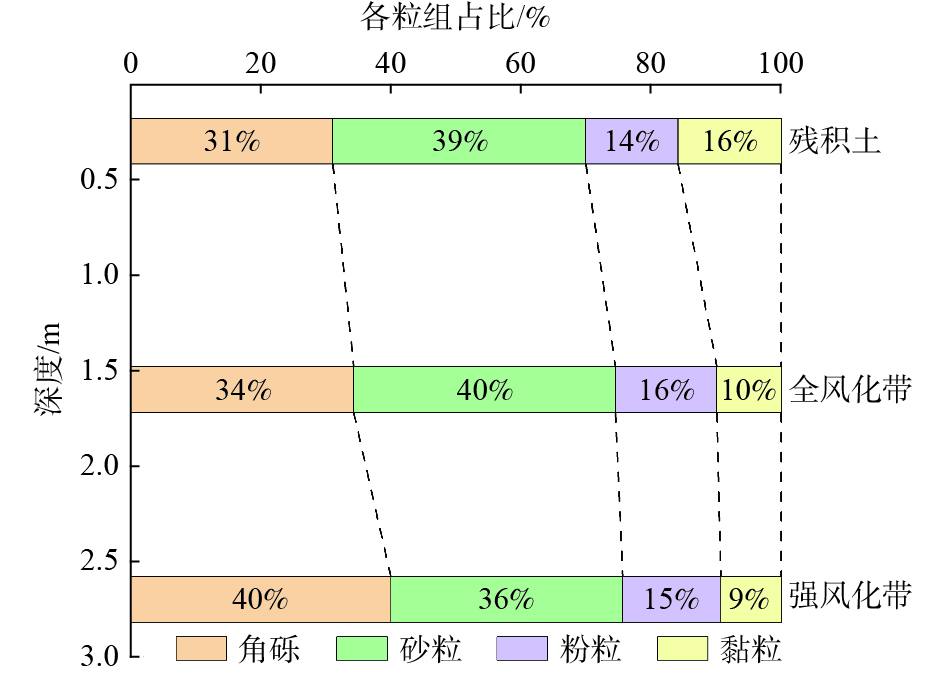

颗粒级配测试结果显示,3 个风化带均为典型的含细粒(粉+黏)砾砂。但是,自残积土至强风化带,黏粒含量逐渐减少,角砾含量逐渐增多,这是风化程度差异的直接表现(图2)。残积土、全风化带、强风化带中稀土元素含量分别为180.8 ,421.2,146.1 μg/g。

表 1 稀土矿试样的基本物理性质Table 1. Physical properties of the RE ore samples编号 试样 天然含水率/% 孔隙度/% 干密度/(kN·m−3) 比重 1-1 残积土 7.33 22.58 17.04 2.71 2-1 全风化带 7.42 21.45 17.16 2.71 3-1 强风化带 7.42 21.07 16.68 2.71 1.2 模拟原地浸矿试验

采用基于原状样的室内柱式常水头淋滤试验模拟原地浸出工艺,浸出液选用工业生产中常用的硫酸铵溶液[12]。前人研究和工业实践表明,硫酸铵溶液质量百分比浓度4%、pH值4.5时浸出效果最好,常用淋滤水头高度为20 cm[13 − 14],浸出8 h 后,稀土元素基本上被浸出[7]。故研究采用上述试验条件进行模拟原地浸矿试验。

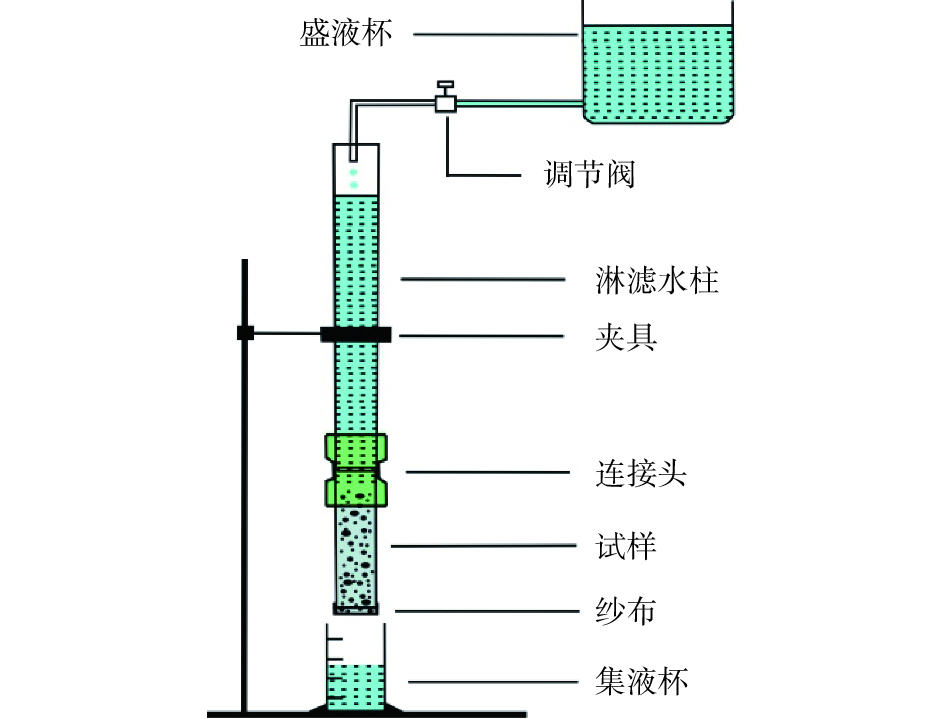

模拟原地浸出试验采用自制的水头控制浸出装置。该装置由盛液杯、调节阀、淋滤水柱、夹具、连接头、试样、纱布、集液杯组成(图3)。为了降低扰动对试验结果的影响,将采集的原状试样两端各去除10 mm,剩余试样直径23 mm、高100 mm。为防止试样在浸矿过程中掉落,在试样底部铺设纱布并绑紧。用连接头将装有试样的聚碳酸酯管和淋滤水柱管连接,并按设计的试验条件进行试验。

浸矿过程中,收集浸出液并记录流量,依据达西公式(式1)计算试样渗透系数:

(1) 式中:K——渗透系数/(cm·s−1);

Q——单位时间内浸出液流量/(cm3·s−1);

ΔH——浸矿液通过稀土矿试样的水头差/cm;

A——试样截面积/cm2;

L——浸矿液流过的试样长度/cm。

1.3 X-CT扫描与图像处理

X-CT扫描采用德国生产的YXLON FF35 高精度X-CT扫描设备。扫描电压210 KV,电流110 μA,射线源与样品距离49 mm,射线源与探测器距离590 mm,总扫描时间0.3 h ,每个切片扫描间隔时间0.56 s 。扫描区位于试样中部。扫描范围是直径21 mm、高19 mm的柱状试样段。

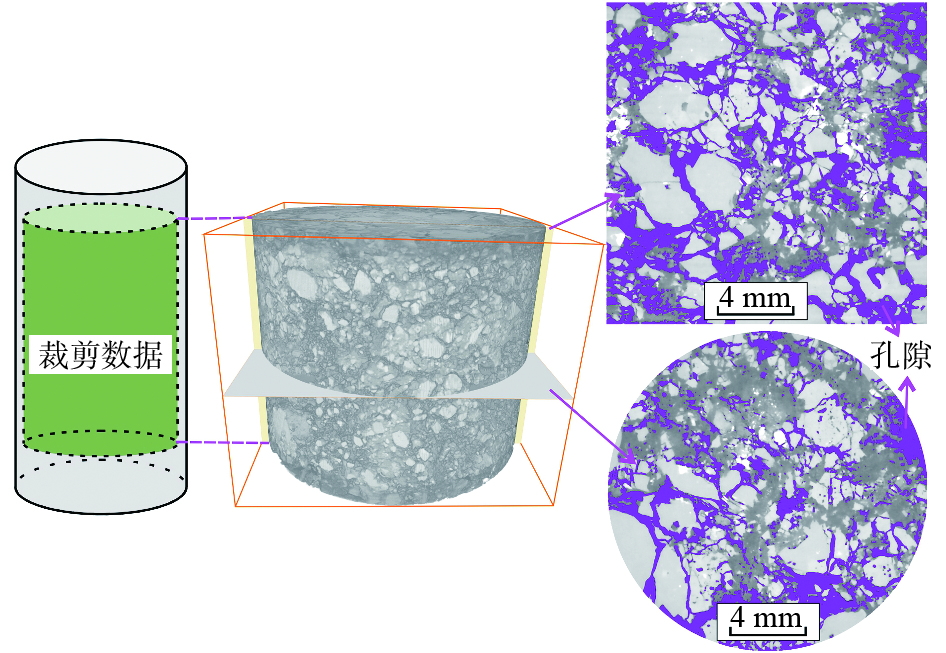

采用影像处理软件Avizo对X-CT扫描图像进行三维成像、构建三维孔隙结构、提取孔隙结构参数。为降低柱式浸矿过程中渗流产生的边壁效应及扫描设备在样品两端成像质量较低的影响,在影像处理过程中裁剪掉两端和靠近管壁的数据,只保留中间直径17 mm、高17 mm的柱状段扫描数据。采用Avizo软件中的图像阈值分割法,得到二值化黑白图像,用于区分图像中的孔隙和固体颗粒(图4)。根据提取的孔隙切片数据,构建三维孔隙网络模型,提取孔隙结构参数。

选取孔径及其分布、孔喉及其分布、配位数、孔隙度、连通性指数等能够表征孔隙特征及其连通性的7个参数定量刻画孔隙结构。其中,孔隙和孔喉直径为采用“最大球”算法计算得到的等效直径[15];配位数表示一个孔隙连接孔喉的个数;连通性指数表示连通的各个孔隙体积的平方和与所有孔隙体积之和的平方的比值,计算公式如式(2):

(2) 式中:Γ——连通性指数;

m——孔隙数量;

Xi——第 i 个孔隙体积。

2. 结果

由于风化程度差异,残积土、全风化带和强风化带天然地在孔隙结构参数和渗透系数上具有依次减小的特征。因此,这 3 带直接的孔隙结构和渗透性没有可比性。但是,从讨论 3 带中稀土矿开采浸出率的角度,浸出前后 3 带孔隙结构和渗透性的变化程度更有实际意义。基于此,本文从 3 带稀土矿体浸出前后孔隙结构参数和渗透系数变化率(即增减幅度)上进行对比分析,变化率按下式计算:

(3) 式中:R——变化率;

Xa——浸矿前参数值;

Xb——浸矿后参数值。

2.1 孔隙和孔喉变化特征

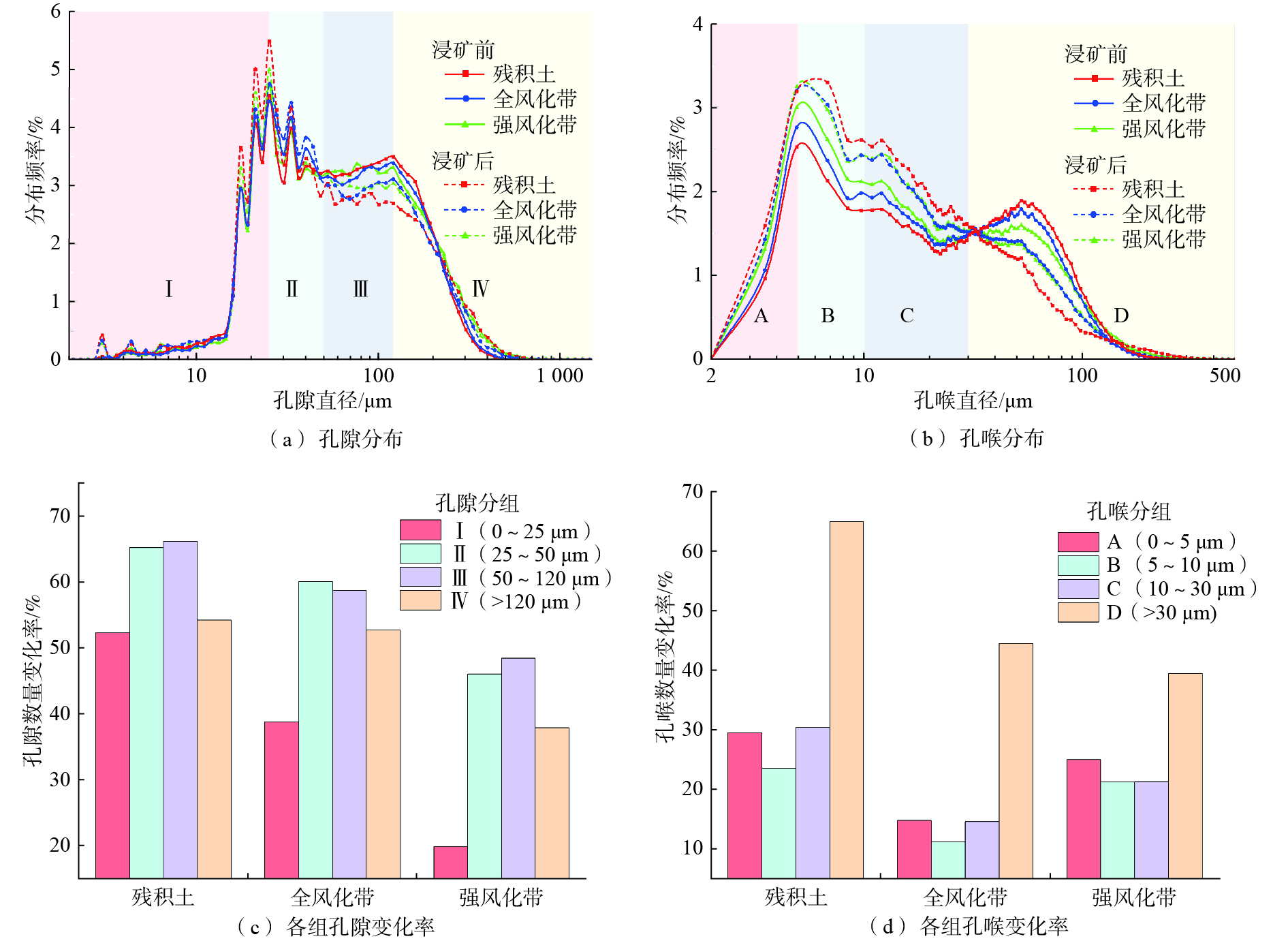

浸矿前后不同风化程度稀土矿试样中的孔隙孔径、孔喉分布显示,浸矿后孔径、孔喉均发生显著变化,见图5 (a)(b)。依据孔径分布特征,可将孔隙分为0~25 μm、25~50 μm、50~120 μm、>120 μm 4 组,分别记为Ⅰ、Ⅱ、Ⅲ、Ⅳ;同样,根据孔喉分布特征,可将孔喉分为0~5 μm、5~10 μm、10~30 μm、>30 μm4 组,分别记为A、B、C、D。浸出后各组孔隙、孔喉含量均显著减少。随着风化程度减弱,各组孔隙及D组孔喉含量降低幅度即变化率减小,变化率分别为20%~52%、46%~65%、48%~66%、38%~54%、39%~65%;A、B、C 3 组孔喉含量变化率分别为:15%~30%、11%~24%、15%~31%,但强风化带孔喉变化率大于全风化带。

2.2 孔隙结构参数与渗透系数变化特征

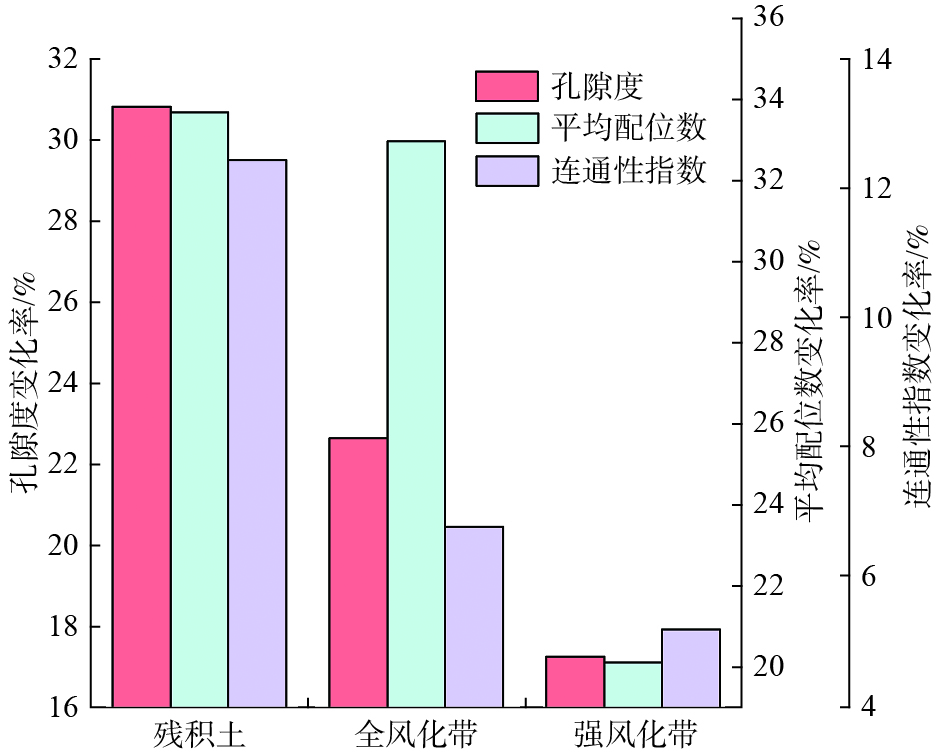

浸出后,孔隙结构参数:孔隙度、连通性指数和平均配位数变化率也随风化程度减弱而减小,变化率分别为17%~31%、5%~12%、20%~34%(图6)。

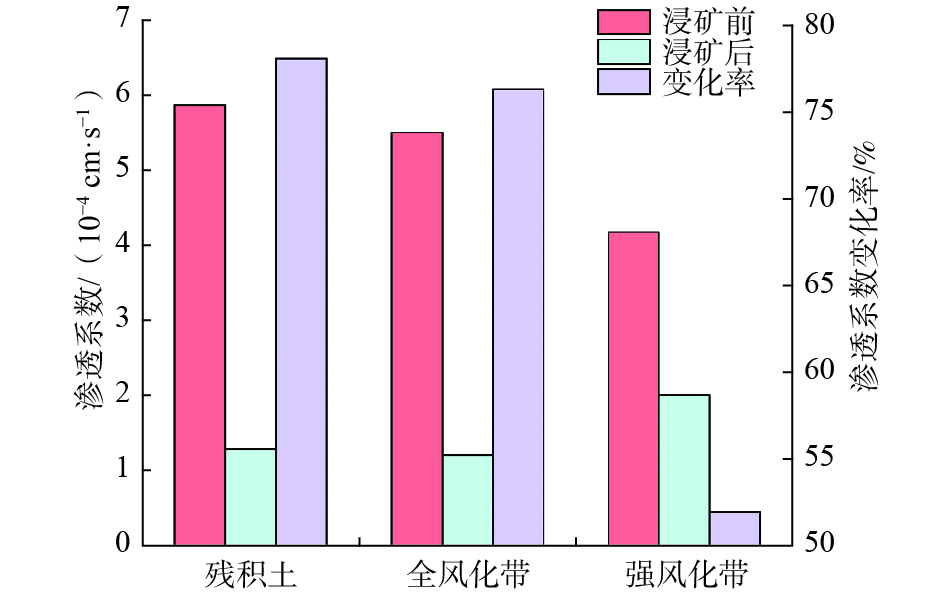

同时,浸出后稀土矿渗透系数显著降低,变化率52%~78%(图7),也呈现随风化程度减弱依次减小的变化特征。如图5(c)(d)、图6所示,比较渗透系数变化率与孔隙结构参数变化率的同步性,与平均配位数变化率一致性最强,其次为IV组孔隙含量变化率。反映出渗透系数与平均配位数相关性最强,>120 μm的大孔隙最利于浸矿液渗流。强风化带稀土矿渗透系数变化率显著小于残积土,显示丰度相近时强风化带浸出率高于后者,更易于开发利用。

3. 讨论

孔隙和孔喉存在于风化带内土体颗粒之间,不同风化带稀土矿孔隙结构和渗透性变化程度显然是浸矿液与土体颗粒化学、物理及力学作用综合差异的反映。

3.1 化学分解作用

不同风化带与酸性浸矿液接触后,浸矿液中H+将导致长石、云母矿物发生如下的化学分解作用:

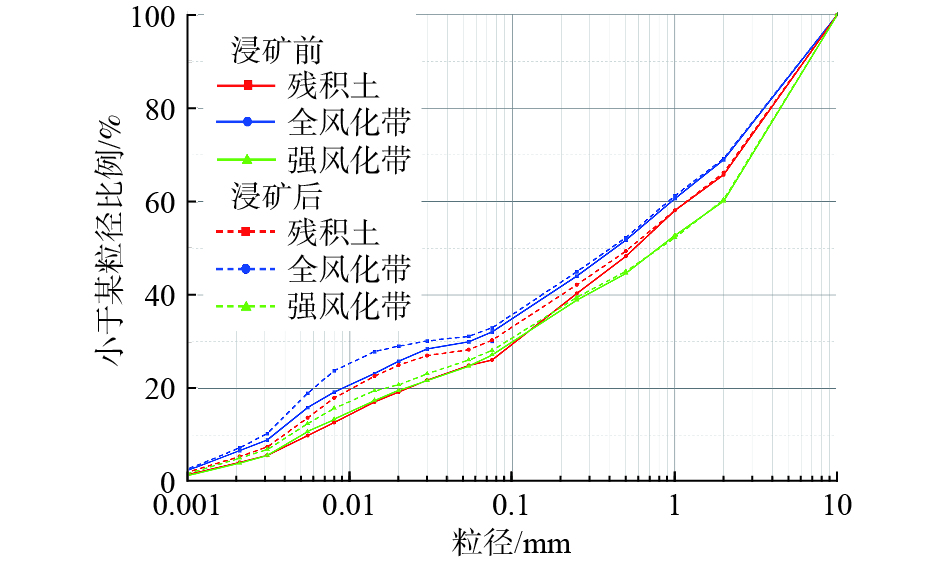

这种作用会加剧长石、云母的化学风化,土体颗粒随之细化,部分生成高岭石、伊利石[16],使得浸矿后试样中黏粒、粉粒等细颗粒含量增加(图8)。残积土、全风化带和强风化带稀土矿试样的黏土矿物含量分别增加27.4%、17.3%、24.1%,残积土稀土矿中黏土矿物增加幅度最大,全风化带稀土矿中黏土矿物增加幅度最小(表2)。黏粒、粉粒等细粒含量增加,会导致稀土矿渗透系数降低[17]。浸矿后颗粒级配变化程度反映其化学分解作用强度随风化程度减弱而减小(图8、表2)。

表 2 稀土矿试样浸出前后矿物组成Table 2. Mineral composition of the RE ore samples before and after leaching编号 试样 全土矿物组成/% 石英 长石 云母 黏土矿物 1-1 残积土 浸矿前 52.5 22.7 11.3 13.5 浸矿后 52.5 20.4 9.9 17.2 2-1 全风化带 浸矿前 46.5 28.6 12.8 12.1 浸矿后 49.3 24.5 12.0 14.2 3-1 强风化带 浸矿前 41.1 31.4 16.3 11.2 浸矿后 45.2 28.5 12.4 13.9 3.2 阳离子交换与团粒分散作用

阳离子交换作用是浸矿过程中最典型的化学作用之一,即:浸矿液中高浓度低价铵离子置换被黏土矿物表面吸附的高价稀土离子。基于黏土矿物的阳离子交换原理,浓度高的低价阳离子置换高价阳离子后,黏粒表面双电层增厚,颗粒间连结力减弱[18]。因此,低价铵离子置换高价稀土离子后,浸矿前团聚成较粗颗粒的黏粒集合体因连结力减弱而不断分散[8],此为浸矿过程中的物理作用。黏粒集合体分散后,浸出后的稀土矿中黏粒、粉粒增加(图8)。同时,分散的细颗粒进入溶液,在孔喉、孔隙内聚集时,便堵塞孔隙、孔喉,造成不同风化带内各组孔隙数量明显降低,见图5(c),更导致各带渗透性均显著降低(图7)。

由于全风化带中稀土丰度最高,残积土和强风化带内稀土丰度相对较低。因此,全风化带稀土矿的离子交换反应最强烈。孔喉中较小的A、B、C 3 组在全风化带中含量变化率显著小于残积土和强风化带,见图5(d),可能与强烈的离子交换作用和团粒分散作用有关。

3.3 细粒迁移作用

浸矿液渗流过程中,当水头大于土体渗透变形的临界水头时,细颗粒会在渗透力作用下随浸矿液迁移。根据式(4)[17]和试样的基本物理性质(表1),理论上残积土、全风化带和强风化带内细颗粒迁移的临界水头分别为13.24 ,13.43,13.50 cm,均小于20 cm的试验水头。

(4) 式中:

L——渗流长度/cm;

Gs——颗粒比重;

n——孔隙度。

因此,在渗透力作用下不同风化带内细颗粒均发生细粒迁移现象。随细颗粒渗流迁移,会增大渗透性;遇细小孔喉、孔隙时,也可能将其堵塞,降低渗透性[19]。由于不同风化带的浸出液均透明、清亮(图9),可以观察到迁移后细粒的堵塞作用更大。在浸矿过程中主要是细粒(<0.075 mm)发生了迁移[20],当渗流水头大于临界水头条件且渗流作用相近时,细粒含量越多,迁移颗粒越多[21]。据此,残积土的细粒迁移最多,渗透系数变化率最大,强化风带的细粒迁移最少,渗透系数变化率最小。

4. 结论

(1)不同风化带稀土矿浸出后孔隙结构和渗透性均显著降低,且渗透系数降低程度与孔隙的平均配位数相关性最强,>120 μm的大孔隙最利于渗流。

(2)不同风化带稀土矿孔隙结构和渗透性的变化特征不同。强风化带的孔隙结构参数和渗透系数变化率(降低幅度)最小。丰度相近时,强风化带稀土矿的浸出率将高于残积土稀土矿,更易于开发利用。

(3)不同风化带稀土矿浸出后孔隙结构参数和渗透系数变化率差异的主要原因是化学分解作用强度、离子交换作用强度和团粒分散作用强度及细粒迁移作用强度的差异,前、后二者在残积土中作用最活跃,中间二者在全风化带中作用最强。强风化带内四者作用最弱,故而其渗透系数变化率(降低幅度)最小。

-

表 1 稀土矿试样的基本物理性质

Table 1 Physical properties of the RE ore samples

编号 试样 天然含水率/% 孔隙度/% 干密度/(kN·m−3) 比重 1-1 残积土 7.33 22.58 17.04 2.71 2-1 全风化带 7.42 21.45 17.16 2.71 3-1 强风化带 7.42 21.07 16.68 2.71 表 2 稀土矿试样浸出前后矿物组成

Table 2 Mineral composition of the RE ore samples before and after leaching

编号 试样 全土矿物组成/% 石英 长石 云母 黏土矿物 1-1 残积土 浸矿前 52.5 22.7 11.3 13.5 浸矿后 52.5 20.4 9.9 17.2 2-1 全风化带 浸矿前 46.5 28.6 12.8 12.1 浸矿后 49.3 24.5 12.0 14.2 3-1 强风化带 浸矿前 41.1 31.4 16.3 11.2 浸矿后 45.2 28.5 12.4 13.9 -

[1] 周贺鹏,谢帆欣,张永兵,等. 离子型稀土矿地球化学特征与物性研究[J]. 稀有金属,2022,46(1):78 − 86. [ZHOU Hepeng,XIE Fanxin,ZHANG Yongbing,et al. Geochemical characteristics and physical properties of ion adsorption type rare earth ore[J]. Chinese Journal of Rare Metals,2022,46(1):78 − 86. (in Chinese with English abstract)] ZHOU Hepeng, XIE Fanxin, ZHANG Yongbing, et al. Geochemical characteristics and physical properties of ion adsorption type rare earth ore[J]. Chinese Journal of Rare Metals, 2022, 46(1): 78 − 86. (in Chinese with English abstract)

[2] 雒恺,马金龙. 花岗岩风化过程中稀土元素迁移富集机制研究进展[J]. 地球科学进展,2022,37(7):692 − 708. [LUO Kai,MA Jinlong. Recent advances in migration and enrichment of rare earth elements during chemical weathering of granite[J]. Advances in Earth Science,2022,37(7):692 − 708. (in Chinese with English abstract)] DOI: 10.11867/j.issn.1001-8166.2022.7.dqkxjz202207003 LUO Kai, MA Jinlong. Recent advances in migration and enrichment of rare earth elements during chemical weathering of granite[J]. Advances in Earth Science, 2022, 37(7): 692 − 708. (in Chinese with English abstract) DOI: 10.11867/j.issn.1001-8166.2022.7.dqkxjz202207003

[3] MOLDOVEANU G A,PAPANGELAKIS V G. Recovery of rare earth elements adsorbed on clay minerals:I. Desorption mechanism[J]. Hydrometallurgy,2012,117:71 − 78.

[4] BORST A M,SMITH M P,FINCH A A,et al. Adsorption of rare earth elements in regolith-hosted clay deposits[J]. Nature Communications,2020,11(1):4386. DOI: 10.1038/s41467-020-17801-5

[5] HE Zhengyan,ZHANG Zhenyue,YU Junxia,et al. Process optimization of rare earth and aluminum leaching from weathered crust elution-deposited rare earth ore with compound ammonium salts[J]. Journal of Rare Earths,2016,34(4):413 − 419. (in Chinese with English abstract DOI: 10.1016/S1002-0721(16)60042-X

[6] WANG Xiaojun,ZHUO Yulong,DENG Shuqiang,et al. Experimental research on the impact of ion exchange and infiltration on the microstructure of rare earth orebody[J]. Advances in Materials Science and Engineering,2017,2017:4762858.

[7] 王晓军,李永欣,黄广黎,等. 离子吸附型稀土浸矿过程渗透系数与孔隙率关系研究[J]. 稀土,2017,38(5):47 − 55. [WANG Xiaojun,LI Yongxin,HUANG Guangli,et al. Research of permeability and porosity in ion-type rare earth leaching process[J]. Chinese Rare Earths,2017,38(5):47 − 55. (in Chinese with English abstract)] WANG Xiaojun, LI Yongxin, HUANG Guangli, et al. Research of permeability and porosity in ion-type rare earth leaching process[J]. Chinese Rare Earths, 2017, 38(5): 47 − 55. (in Chinese with English abstract)

[8] ZHAO Kui,ZHUO Yulong,WANG Xiaojun,et al. Aggregate evolution mechanism during ion-adsorption rare earth ore leaching[J]. Advances in Materials Science and Engineering,2018,2018:4206836.

[9] YIN Shenghua,CHEN Xun,YAN Rongfu,et al. Pore structure characterization of undisturbed weathered crust elution-deposited rare earth ore based on X-ray micro-CT scanning[J]. Minerals,2021,11(3):236. DOI: 10.3390/min11030236

[10] 付伟,赵芹,罗鹏,等. 中国南方离子吸附型稀土矿床成矿类型及其母岩控矿因素探讨[J]. 地质学报,2022,96(11):3901 − 3925. [FU Wei,ZHAO Qin,LUO Peng,et al. Mineralization diversity of ion-adsorption type REE deposit in Southern China and the critical influence of parent rocks[J]. Acta Geologica Sinica,2022,96(11):3901 − 3925. (in Chinese with English abstract)] DOI: 10.3969/j.issn.0001-5717.2022.11.016 FU Wei, ZHAO Qin, LUO Peng, et al. Mineralization diversity of ion-adsorption type REE deposit in Southern China and the critical influence of parent rocks[J]. Acta Geologica Sinica, 2022, 96(11): 3901 − 3925. (in Chinese with English abstract) DOI: 10.3969/j.issn.0001-5717.2022.11.016

[11] 王运,赵碧波,杨兰,等. 赣南足洞特大离子吸附型重稀土矿床地球化学特征及成矿意义[J]. 稀土,2023,44(6):51 − 63. [WANG Yun, ZHAO Bibo, YANG Lan, et al. Geochemical characteristics and metallogenic implications of extra large-scale ion adsorption type heavy rare earth deposit in Zudong, southern Jiangxi[J]. Chinese Rare Earths,2023,44(6):51 − 63. (in Chinese with English abstract)] WANG Yun, ZHAO Bibo, YANG Lan, et al. Geochemical characteristics and metallogenic implications of extra large-scale ion adsorption type heavy rare earth deposit in Zudong, southern Jiangxi[J]. Chinese Rare Earths, 2023, 44(6): 51 − 63. (in Chinese with English abstract)

[12] 池汝安,刘雪梅. 风化壳淋积型稀土矿开发的现状及展望[J]. 中国稀土学报,2019,37(2):129 − 140. [CHI Ru’an, LIU Xuemei. Prospect and development of weathered crust elution-deposited rare earth ore[J]. Journal of the Chinese Society of Rare Earths,2019,37(2):129 − 140. (in Chinese with English abstract)] CHI Ru’an, LIU Xuemei. Prospect and development of weathered crust elution-deposited rare earth ore[J]. Journal of the Chinese Society of Rare Earths, 2019, 37(2): 129 − 140. (in Chinese with English abstract)

[13] 柯兆华,邱小英,郭安,等. 离子型稀土矿原地浸矿影响因素研究[J]. 稀有金属与硬质合金,2021,49(4):1 − 5. [KE Zhaohua, QIU Xiaoying, GUO An, et al. Study on influencing factors of in-situ leaching of ionic rare earth ore[J]. Rare Metals and Cemented Carbides,2021,49(4):1 − 5. (in Chinese with English abstract)] KE Zhaohua, QIU Xiaoying, GUO An, et al. Study on influencing factors of in-situ leaching of ionic rare earth ore[J]. Rare Metals and Cemented Carbides, 2021, 49(4): 1 − 5. (in Chinese with English abstract)

[14] LI Liang,WANG Li,LIU Qiaochu. Effects of salinity and pH on clay colloid aggregation in ion-adsorption-type rare earth ore suspensions by light scattering analysis[J]. Minerals,2022,13(1):38. DOI: 10.3390/min13010038

[15] 解朝阳,张巍,姚东方,等. 基于最大球算法定量表征土体空间孔隙网络[J]. 工程地质学报,2020,28(1):60 − 68. [Xie Chaoyang,Zhang Wei,Yao Dongfang, et al. Quantitative characterization of spatial pore network of soils based on maximal-balls algorithm[J]. Journal of Engineering Geology,2020,28(1):60 − 68. (in Chinese with English abstract)] Xie Chaoyang, Zhang Wei, Yao Dongfang, et al. Quantitative characterization of spatial pore network of soils based on maximal-balls algorithm[J]. Journal of Engineering Geology, 2020, 28(1): 60 − 68. (in Chinese with English abstract)

[16] CHEN Lingkang,JIN Xiongwei,CHEN Haixia,et al. Grain size distribution and clay mineral distinction of rare earth ore through different methods[J]. Minerals,2020,10(4):353. DOI: 10.3390/min10040353

[17] 李广信,张丙印,于玉贞. 土力学[M]. 3版. 北京:清华大学出版社,2022. [LI Guangxin,ZHANG Bingyin,YU Yuzhen. Soil mechanics[M]. 3rd ed. Beijing:Tsinghua University Press,2022. (in Chinese )] LI Guangxin, ZHANG Bingyin, YU Yuzhen. Soil mechanics[M]. 3rd ed. Beijing: Tsinghua University Press, 2022. (in Chinese )

[18] XIAO Yanfei,GAO Guohua,HUANG Li,et al. A discussion on the leaching process of the ion-adsorption type rare earth ore with the electrical double layer model[J]. Minerals Engineering,2018,120:35 − 43. DOI: 10.1016/j.mineng.2018.02.015

[19] WILSON G V. Mechanisms of ephemeral gully erosion caused by constant flow through a continuous soil-pipe[J]. Earth Surface Processes and Landforms,2009,34(14):1858 − 1866. DOI: 10.1002/esp.1869

[20] 刘德峰,张臻悦,池汝安. 风化壳淋积型稀土矿原地浸出微观渗流机制[J]. 稀土,2020,41(4):1 − 11. [LIU Defeng,ZHANG Zhenyue,CHI Ru’an. Microscopic seepage mechanism during in-situ leaching of weathered crust elution-deposited rare earth ores[J]. Chinese Rare Earths,2020,41(4):1 − 11. (in Chinese with English abstract)] LIU Defeng, ZHANG Zhenyue, CHI Ru’an. Microscopic seepage mechanism during in-situ leaching of weathered crust elution-deposited rare earth ores[J]. Chinese Rare Earths, 2020, 41(4): 1 − 11. (in Chinese with English abstract)

[21] 戴传山,祁芸芝,雷海燕,等. 悬浮微小颗粒对多孔介质渗流特性影响的实验研究[J]. 水文地质工程地质,2016,43(6):1 − 6. [DAI Chuanshan,QI Yunzhi,LEI Haiyan,et al. Deposition effect of suspended microparticle on the local permeability in porous media[J]. Hydrogeology & Engineering Geology,2016,43(6):1 − 6. (in Chinese with English abstract)] DAI Chuanshan, QI Yunzhi, LEI Haiyan, et al. Deposition effect of suspended microparticle on the local permeability in porous media[J]. Hydrogeology & Engineering Geology, 2016, 43(6): 1 − 6. (in Chinese with English abstract)

下载:

下载:

邮件订阅

邮件订阅 RSS

RSS